In a significant step towards sustainable lunar exploration, Sierra Space is working on a pioneering device designed to produce oxygen under conditions mimicking those on the moon. The initiative, taking place at NASA’s Johnson Space Center, involves transforming lunar regolith—composed of dust and debris similar to that on the moon—into breathable oxygen.

The engineers, gathered around a silvery, box-like machine enshrined in colorful wires, kicked off the experiment by feeding the apparatus small amounts of this lunar-like soil. The process saw the regolith heated to extreme temperatures exceeding 1,650°C, where a reaction produced bubbling oxygen-containing molecules. "We’ve tested everything we can on Earth now. The next step is going to the moon,” states Brant White, program manager for Sierra Space.

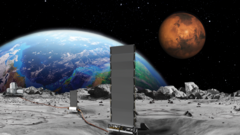

This experiment is part of a larger initiative to develop technologies that could sustain astronauts living on lunar bases in the future. The need for oxygen is critical not just for breathing but also for rocket fuel, necessary for space travel beyond the moon, including potential missions to Mars. Beyond oxygen extraction, there exists a potential to obtain metals from lunar soil, which could be used for various tasks, potentially saving billions compared to transporting supplies from Earth.

However, extracting oxygen from lunar regolith poses unique challenges due to the moon's lower gravity and harsh conditions. Sierra Space is employing a large spherical chamber to replicate the moon's vacuum and temperature extremes. Notably, the behavior of materials under lunar gravity cannot be fully tested on Earth, leading some experts, like Paul Burke from Johns Hopkins University, to warn that current oxygen-extraction technologies may encounter difficulties in such an environment.

Researchers like Burke are looking at various solutions to this dilemma, such as vibrating extraction equipment and refining electrode designs to facilitate bubble extraction. Meanwhile, Sierra Space's carbothermal process mitigates some of these issues, allowing oxygen bubbles to form more freely, making the extraction more efficient.

According to estimates, each astronaut may need daily oxygen equivalent to two or three kilograms of regolith. Nevertheless, life support systems would likely recycle exhaled oxygen, minimizing the amount of regolith processing needed.

In collaboration with MIT, Palak Patel has also been investigating methods to extract oxygen and metals using molten regolith electrolysis. Her research aims to reduce the number of resupply missions needed by developing machinery capable of generating materials directly on the moon. To solve potential detachment problems tied to lunar gravity, Patel and her team have innovated a "sonicator" to push bubbles free using sound waves.

The excitement surrounding the utilization of lunar regolith extends beyond oxygen. In separate experiments, Patel’s group explored turning regolith into a sturdy glass-like material. This refinement could yield robust hollow bricks suitable for construction on the moon, paving the way for future lunar infrastructure.

As the Artemis mission plans to land astronauts on the lunar surface by 2027, the successful development of oxygen-extracting technology stands as a pillar for future lunar habitation and the ambitions of deeper space exploration.

The engineers, gathered around a silvery, box-like machine enshrined in colorful wires, kicked off the experiment by feeding the apparatus small amounts of this lunar-like soil. The process saw the regolith heated to extreme temperatures exceeding 1,650°C, where a reaction produced bubbling oxygen-containing molecules. "We’ve tested everything we can on Earth now. The next step is going to the moon,” states Brant White, program manager for Sierra Space.

This experiment is part of a larger initiative to develop technologies that could sustain astronauts living on lunar bases in the future. The need for oxygen is critical not just for breathing but also for rocket fuel, necessary for space travel beyond the moon, including potential missions to Mars. Beyond oxygen extraction, there exists a potential to obtain metals from lunar soil, which could be used for various tasks, potentially saving billions compared to transporting supplies from Earth.

However, extracting oxygen from lunar regolith poses unique challenges due to the moon's lower gravity and harsh conditions. Sierra Space is employing a large spherical chamber to replicate the moon's vacuum and temperature extremes. Notably, the behavior of materials under lunar gravity cannot be fully tested on Earth, leading some experts, like Paul Burke from Johns Hopkins University, to warn that current oxygen-extraction technologies may encounter difficulties in such an environment.

Researchers like Burke are looking at various solutions to this dilemma, such as vibrating extraction equipment and refining electrode designs to facilitate bubble extraction. Meanwhile, Sierra Space's carbothermal process mitigates some of these issues, allowing oxygen bubbles to form more freely, making the extraction more efficient.

According to estimates, each astronaut may need daily oxygen equivalent to two or three kilograms of regolith. Nevertheless, life support systems would likely recycle exhaled oxygen, minimizing the amount of regolith processing needed.

In collaboration with MIT, Palak Patel has also been investigating methods to extract oxygen and metals using molten regolith electrolysis. Her research aims to reduce the number of resupply missions needed by developing machinery capable of generating materials directly on the moon. To solve potential detachment problems tied to lunar gravity, Patel and her team have innovated a "sonicator" to push bubbles free using sound waves.

The excitement surrounding the utilization of lunar regolith extends beyond oxygen. In separate experiments, Patel’s group explored turning regolith into a sturdy glass-like material. This refinement could yield robust hollow bricks suitable for construction on the moon, paving the way for future lunar infrastructure.

As the Artemis mission plans to land astronauts on the lunar surface by 2027, the successful development of oxygen-extracting technology stands as a pillar for future lunar habitation and the ambitions of deeper space exploration.